What is vacuum coating technology?

As technology advances and manufacturing processes evolve, surface treatments like metal coating have become essential across various industries. From aerospace and automotive to electronics, metal coatings enhance durability, appearance, and performance. Unlike traditional painting methods, metal coating technology offers improved corrosion resistance, enhanced mechanical properties, and a polished finish.

However, older coating methods often struggle with issues like poor adhesion on certain materials or difficulty coating specific surfaces. Enter vacuum coating technology—a game-changing solution developed through years of research to overcome these limitations.

Table of Contents

ToggleⅠ.What is vacuum coating technology?

Vacuum coating technology originated in the 1930s, and has been widely used in the fields of electronics, decoration, lighting and communication since the 1980s. Vacuum coating technology refers to a high degree of vacuum environment, through physical or chemical methods, the coating material into a gaseous state of molecules or atoms deposited on the surface of the substrate to form a thin film, so that the solid surface with wear-resistant, high-temperature, corrosion-resistant, oxidation-resistant, anti-radiation, conductive, conductive, insulating and decorative and so on many better than the solid material itself, to achieve product quality, prolong the product life, energy saving and obtaining significant technology. Life, energy savings and significant technical and economic benefits of the role of this process involve the evaporation of materials, condensation and chemical reactions, and ultimately realize the improvement and enhancement of the surface properties of the substrate. The vacuum environment provides dust-free, low gas interference conditions that help to obtain high purity, high uniformity coating layers.

Vacuum coating is a novel new technology for material synthesis and processing, an important part of the surface engineering technology field. Compared with electroplating technology, vacuum coating technology has less pollution, lower energy consumption, lower cost, stronger decorative effect and metallic sense, so vacuum coating technology is regarded as one of the most promising and important technologies, and has shown attractive market prospects in the development of high-tech industrialization.

There are two main methods of vacuum coating: thermal evaporation coating and magnetron sputtering coating, and the commonly used method is thermal evaporation coating. The working principle of the vacuum thermal evaporation coating method is to evaporate the solid in a vacuum environment so that it will be converted into a gaseous state and finally deposited on the surface of the coated product. The vacuum thermal evaporation coating method has two most commonly used heating methods: resistance heating and electron gun heating. Resistance heating is to make the resistance emit heat by energizing, so as to achieve the purpose of heating the coated material; electron gun heating is achieved by an electron beam directly hitting the coating material, generating heat and heating up the coating material.

Magnetron sputtering coating refers to the process of evaporating the metal material into a gas in a vacuum environment and then using ion or electron beams to strike and deposit the metal atoms into the target material surface to form a metal film. Compared with the traditional electroplating or physical vapor deposition technology, the vacuum coating technology provides more accurate sputtering method, which can realize the high purity and high adhesion of metal film.

Compared with traditional electroplating and hot-dip coating technology, vacuum coating technology has three main advantages: first, vacuum coating technology does not affect the quality of the coated material. When heating the coated material, vacuum coating technology does not require high temperature, so there will be no deformation or reduction in the material properties of the coated material. Second, a wide range of raw materials for evaporation can be freely selected, making it easier to control the composition and structure of the coated material. Finally, the coating process does not produce harmful gases and liquids, so it will not greatly affect the surrounding environment.

Ⅱ.How does vacuum coating technology operate?

The process of vacuum coating technology usually includes the following key steps:

1. Cleaning: First of all, the coated material needs to be cleaned on the surface. Rigorous cleaning can effectively remove grease, dirt and other adhering impurities adhering to the material surface, so as to make the surface of the target material smoother and more uniform, thus ensuring the quality and dimensional stability of the metal film.

2. Treatment: After cleaning, the target material needs to be surface treated. At present, the commonly used surface treatment is polarization and activation treatment. The treatment method can help make the surface smoother and facilitate the uniform deposition of the metal film on the target material surface.

3. Establishment and maintenance of vacuum system: A vacuum pump is utilized to pump out the air in the coating chamber to achieve the required vacuum. The control of the vacuum is critical to the quality of the coating as it affects the transport and distribution of the evaporated material. The vacuum environment needs to be kept stable from external contamination and fluctuations to ensure the uniformity and purity of the film layer.

4. Coating: Thin film coating is an important step of the overall coating process. At this stage, preparation methods related to the preparation target include vacuum ion plating, jet forming, sputtering, and thermal evaporation. All of these methods will be carried out in a low pressure environment to ensure that a high-quality metal film is obtained.

5. Testing: After the coating is completed, the metal film needs to be tested to ensure that it meets the process requirements, these tests usually include film thickness, uniformity, adhesion and some other surface properties.

Ⅲ.How is vacuum coating technology applied in the bottle industry?

With people’s pursuit of quality of life and awareness of health increasing, the development of water bottle manufacturing has attracted more attention in recent years. In the bottle industry, vacuum coating technology as a surface treatment, is widely used in stainless steel insulation bottles, insulated jars, and other products. In order to improve the ornamental degree and service life of these products, bottle manufacturers began to use vacuum coating technology to carry out surface treatment. In this way, stainless steel bottles are covered with a layer of metal film on the surface, thereby increasing the corrosion resistance, scratch resistance, thermal insulation performance and other aspects of performance.

The application of vacuum coating technology in the bottle industry mainly includes the following aspects:

1. Antibacterial treatment

Vacuum coating technology can realize the antibacterial treatment of the surface of the bottle. The coating can prevent bacteria from growing on the surface of the bottles, thus reducing the risk of bacterial infection.

2. Improve the corrosion resistance of the bottles

Surface treatment through the vacuum coating technology can make the surface of the bottles to form a good anti-corrosion performance of the protective film, so as to extend the service life of the bottles.

3. Improve the heat preservation performance of the bottles

Vacuum coating technology through the preparation of the surface film layer of the bottle has a high thermal conductivity and thermal insulation performance, can help the bottle better maintain its temperature and thermal insulation performance.

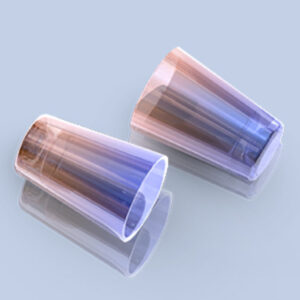

4. Improve the appearance quality of the cups and pots

The vacuum coating technology can make the surface of the bottle show a good metal texture so that the whole bottle appears more beautiful, exquisite.

Ⅳ.What is the development trend of vacuum coating technology in the bottle industry?

Vacuum coating technology in the water bottle industry in a development trend, one of the reasons is that it can improve the added value and market competitiveness of the product. With the improvement of living standards and the increasing demand for product quality, bottle manufacturers will pay more attention to the quality of the coating. In order to better meet the needs of consumers, manufacturers will strengthen their own technological innovation and continuously improve the quality of coating. The following is the development trend of this technology in the bottle industry:

1. Diversified coating technology

Traditional vacuum coating technology can only achieve a single coating, can not meet the consumer demand for diversity and personalization. Therefore, the development of diverse coating technology has become a trend in the bottle industry. Such as high-performance materials coating, emerging materials coating, intelligent coating technology and environmentally friendly coating technology, etc., have made great progress in improving product quality and functionality, reducing production costs and improving production efficiency, environmentally friendly, and so on.

2. Diversified colors and patterns

With the continuous expansion of the market and for personalized, differentiated products increasing demand, bottle manufacturers will continue to introduce a more diverse range of colors and patterns to meet the needs of consumers for personal style and taste.

3. Increase environmental performance

With people’s awareness of environmental protection, in the future, bottle manufacturers will pay more attention to the coating process of environmental protection. They will use more environmentally friendly chemicals for coating, thus reducing the pollution of the environment.

4. Innovative application fields

Vacuum coating technology is continuously progressing and innovating, and in the future, it will be widely used and developed in more application fields, such as high-end tableware, kitchenware, and other fields.

In summary, with the continuous change of market demand and the continuous progress of technology, vacuum coating technology in the bottle industry will continue to be developed and applied. Manufacturers should pay more attention to the application of coating technology in the bottle products to improve product quality, thermal insulation performance and other aspects of performance, and to provide consumers with a better product experience.